The Old Britts oil gauge and mounting system will be using three types of gel filled gauges;

The gauges will go up to 100 psi and are a lot more acurate than the old gauges we used to sell. The old gauges would read practically zero after the bike got warm, where this gauge does drop pressure reading, but maintains a positive reading. On my test bike, I am running around 80 psi, and during a long ride in 80+ temperatures, the new gauge would read 50 psi at around 4000 rpm and 30 psi at idle.

Pricing:

We will be selling the oil gauge and mounting kit in 12 different kits and the prices quoted are current as of 02/12/21.

The basic kit.

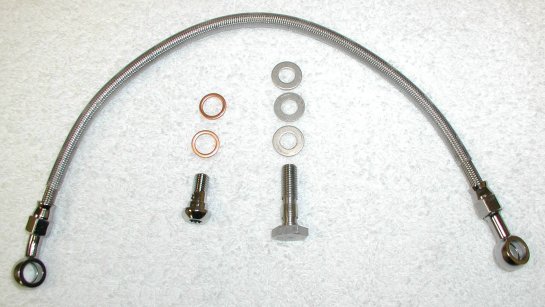

Our basic oil gauge kits include, mounting bracket, oil pressure gauge, one 15 1/4" braided oil line from left rocker feed to the gauge, five sealing washers and one double banjo bolt for the left rocker feed and one single banjo bolt for the oil gauge. Depending on the type of banjos on your existing rocker feeds, we make two oil line kits. If you have the original banjos (we call old banjos with an I.D. of approximately .31"), you want to order the kit with the old banjos; otherwise order the kit with the new banjos (with an I.D. of approximately .395").

The new banjo will be a bit sloppy on the stainless banjo bolt supplied with the old line kits, but the larger sealing washers will seal this banjo properly.

The upgrade kit.

Our upgrade oil gauge kits include mounting bracket, oil pressure gauge and a complete oil line kit.

The kits includes:

The deluxe kit.

Our deluxe oil gauge assembly consists of the mounting bracket, oil pressure gauge and a complete oil line kit with all stainless fittings. The oil line kit looks just like the oil line kit for the upgrade kit, above, except all the fittings are stainless steel.

I know a lot has been written discouraging the use of an oil pressure gauge, but after my experiences racing a 750 Combat and hearing stories from customers, I am convinced that I do not want to ride a Commando without a pressure gauge.

First: On my test bike I could get an idea about how hot my engine was getting by how low the gauge was reading. I would get a reading around 30 psi at idle on a warm engine. This reading would go as low as 15 psi when I was doing a lot of stop and go driving and the engine was not happy. Once I got back up to speed for a bit, I would see a slight increase in pressure. I am sure the readings will differ on all bikes, but after some time, you will get a feeling for what the readings mean.

Second: On my race bike, a 72 Combat, the first year racing I would lose all pressure after several laps. I was using a different gauge, but I could tell something was wrong. The problem was the design of the 72 oil return and after fixing the design problem, my gauge showed the problem fixed. I wrote an article about the 72 design problem -- Oil pressure loss on Norton 750 cc Commandos, 1972 and 1973

Third: Skip Schloss of Flying Fish Motor Cycles in Montana (406-862-6895) rebuilt a customers engine that had burned up the rod bearings and when testing the rebuilt engine, he discovered low oil pressure. It was pumping about 25 psi. when cold, but not more than 5 or 10 when hot, at 4000 RPM. The rule of thumb is 10 psi per 1000 rpm. He had rebuilt the oil pump, but did not surface the pump body, just the end plate. After much checking, he discovered oil leaking between the oil pump body and the end plate. The pump body had not been touched since it left the factory and after surfacing the pump body he got 75 psi on startup. The stock oil pressure release is factory set to 45 to 50 psi and by adding shims you can increase the pressure, but make sure you are using braided steel rocker feed oil lines for the increased oil pressure.

Lastly: I talked to two customers who have had a major brakedown of the oil system in the timing cover. One had an oil gauge and knew something was wrong when he was not getting the same pressure readings as before. We did not know what was causing the lack of oil pressure to the head since the return oil to the tank looked normal. After several tests, he finally had to remove the timing cover and found that the oil seal around the crank shaft had blown. This caused no oil to go to the head, but just return to the oil tank.

The other customer had a bike that the previous owner had forgotten to install the rubber seal between the oil pump and the timing cover.

He also had plenty of oil going back into the oil tank, but just a mist going to the head. I forgot how he discovered the

problem, but since he did not have an oil gauge, he was lucky to discover the problem before any major damage was done.

The mounting system: The mounting system consists of the housing that the gauge fits into, an aluminum stand pipe that goes through the center of the triple clamp down tube and a braided steel oil line. The housing is milled to slide over the handle bar between the handle bar clamps. The housing has a step that takes an o-ring to provide some shock mounting for the gauge.

The gauge is threaded into the pipe at the top end and the bottom end is Heli Coiled to accept a standard rocker banjo bolt. The bottom end is also threaded on the outside to accept a stepped nut to bolt the whole assembly firmly to the triple clamps.

We will be providing two methods to attach the gauge to your left side rocker feed.

One method will be a short braided steel line and double banjo bolt to attach the gauge to your left rocker feed

and a single banjo bolt to attach this line to the bottom of the gauge pipe.

The other method will be a complete braided steel rocker feed which is described in the installation section, below.

Installation:

These rocker feed lines are designed to be installed as the following pictures show. The fittings are arrainged on the lines so the banjos line up with the banjo bolt holes. The top line can only be installed one way, with the curved banjos, curving away from the engine. The line from the timing cover has the straight banjo facing down from the timing cover and looping twards the center of the bike and the curved banjo mounting on the right side of the cylinder head, on the outside of the top line. The domed banjo bolts take a 7/32 allen wrench.

This page was written and designed by F. H. Eaton & Associates if you have any questions or comments please contact us at info@fheaton.com